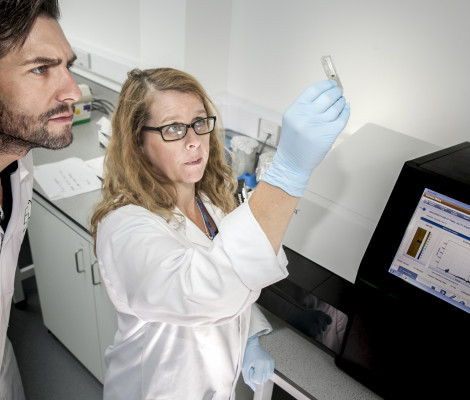

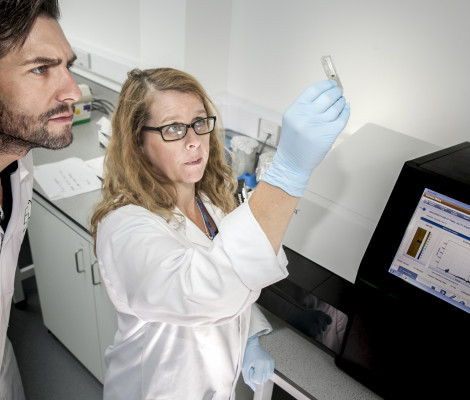

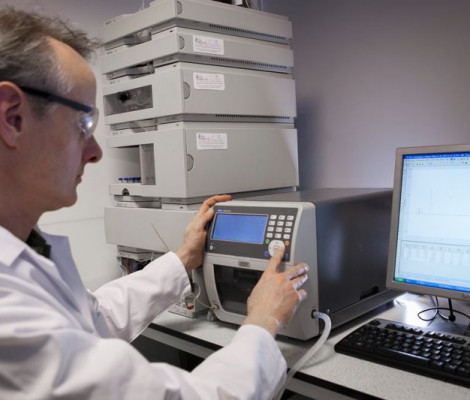

Agilent 2200 TapeStation nucleic acids system

The 2200 TapeStation is ideal for the very rapid characterisation of DNA or RNA samples, including quality assessment, establishing DNA/RNA size ranges and quantification.

Covering a broad spectrum of biorefining technologies, from feedstock assessment to product evaluation, our team of biologists, chemists and innovation advisors specialise in making the most out of biorenewable materials. We develop methods at laboratory scale and scale up processes to demonstrate their commercial potential, typically at the 1-100litre or 1-100kg scale.

As well as laboratory-based support, we also add value through market research activity and product or customer discovery research. Many businesses see us as an extension to their own team, where we provide an extra set of ideas to help solve a process challenge or accelerate a product or service improvement. All our facilities are open-access, if you know what you want to do but don’t have the equipment to do it, then we can also arrange for you to spend time in our laboratory working alongside our experienced team.

To find out more about our biorefining capabilities and our equipment, please explore the sections below.

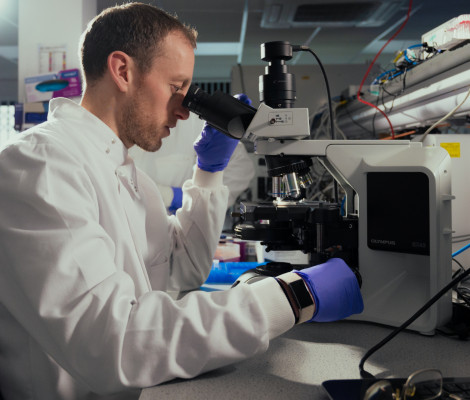

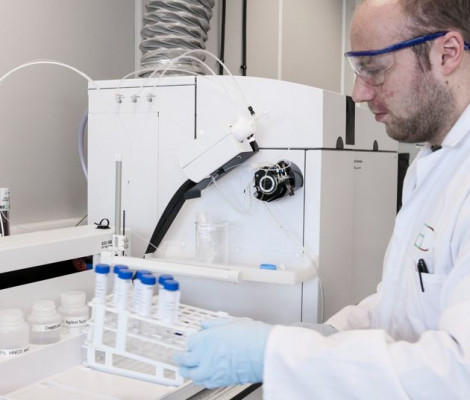

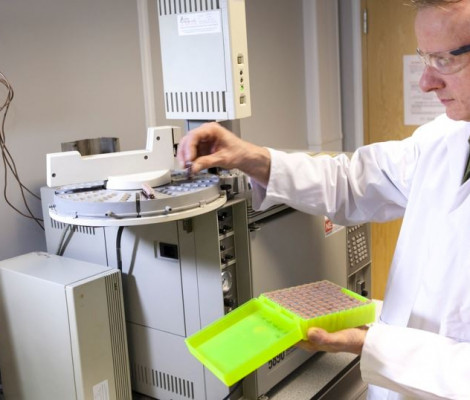

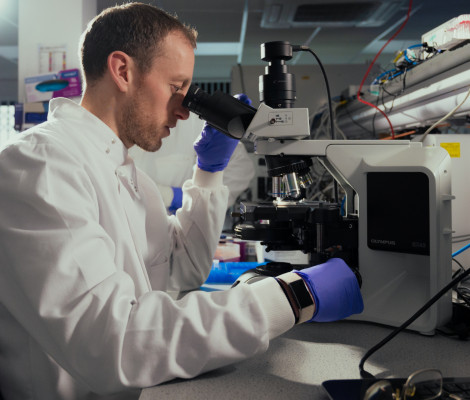

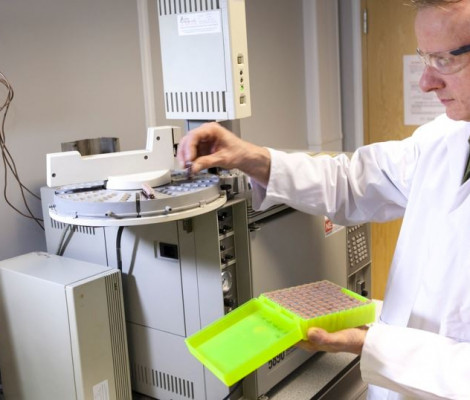

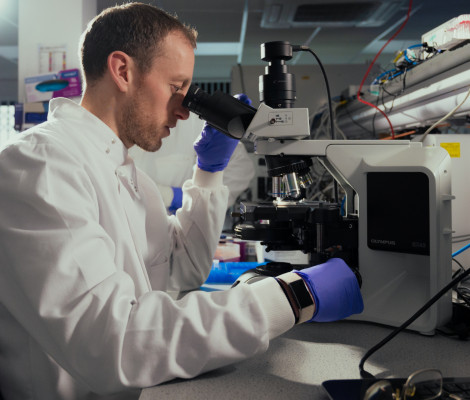

It is often necessary to determine the physical and chemical properties of the raw materials used in a specific project at the start of the work. This typically involves specific technologies that focus in on particular properties, such as the range of chemical elements in a source of biomass or the amount of water present. We have a range of capabilities to look at different feedstock properties including various types of chromatography, water analysis, oxidative stability, nucleic acid analysis and microscopy. Using these technologies allows a detailed profile of physical and chemical properties to be generated that then determines the next steps in processing a particular type of bio-based raw material.

The 2200 TapeStation is ideal for the very rapid characterisation of DNA or RNA samples, including quality assessment, establishing DNA/RNA size ranges and quantification.

We have a variety of analytical equipment available at the centre.

The Benchtop NMR Analyser is based on Nuclear Magnetic Resonance (NMR) and allows for fast, accurate, reproducible and solvent-free measurement of oil, fat and moisture in oil seeds, seed cake and foodstuffs.

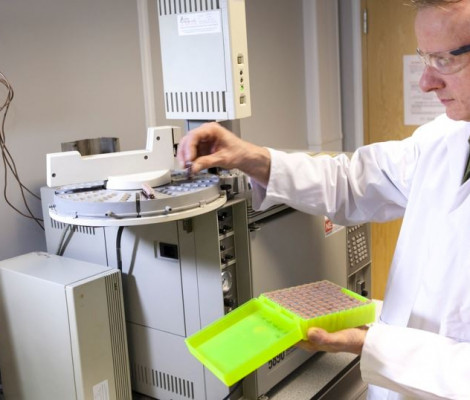

Gas chromatography (GC) is a flexible technique that allows separation and quantification of chemical substances found within a complex mixture.

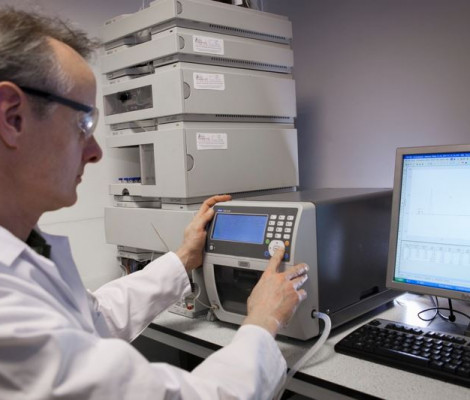

High Performance Liquid Chromatography (HPLC) is a flexible technique that allows separation and quantification of chemical substances found within a complex mixture.

The Agilent 7700x ICP-MS is capable of measuring metal and non-metal elements in concentrations of parts per trillion.

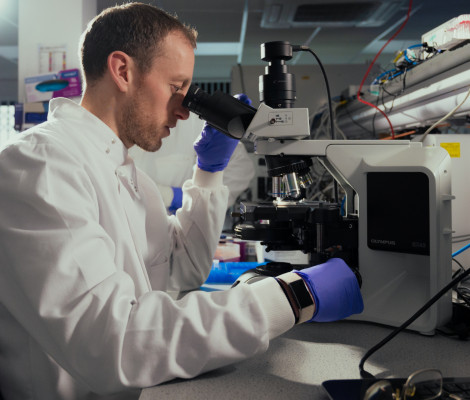

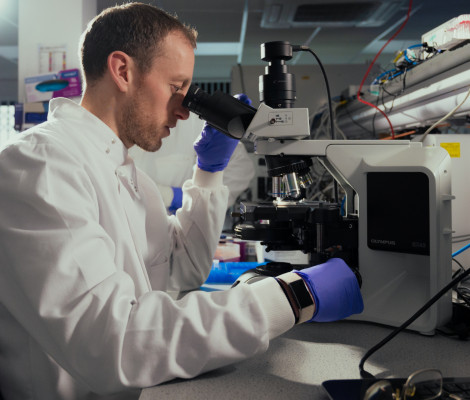

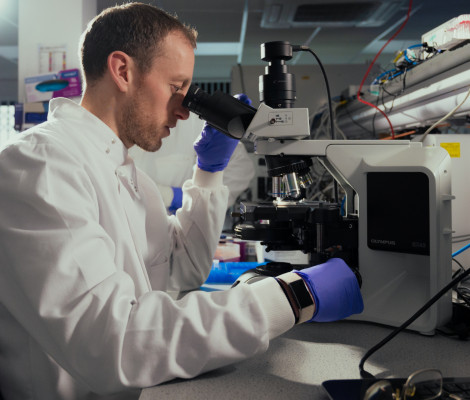

We have established a set of molecular analysis labs to enable a variety of genetic analysis applications to be carried out.

Our microbiology laboratory offers a range of equipment allowing users to safely handle, store and work with a variety of aerobic and anaerobic microbes, at ACDP hazard category II level.

The Metrohm Rancimat helps us determine the oxidation stability of natural fats and oils. The instrument works on the principle of passing air through a test sample at an elevated temperature, causing accelerated aging of the sample.

The Hache spectrophotometer offers a safe, easy and versatile system to measure various characteristics of liquid samples.

Processing biomass to generate or purify specific products normally requires the development of some form of biological, chemical or physical system. This can be a genetically modified microbe or a novel technology such as a physical separation instrument. We have the facilities to allow businesses and other organisations to develop new biological and other technological systems in partnership with our technical teams. This includes state-of-the-art molecular biology and microbiology facilities as well as a Flexi Hall that provides access to plug and play utilities including steam, compressed air, vacuum and a range of water grades. Our open access facilities mean new systems can be developed at to accelerate innovation development.

We have several bioreactor systems, which allow the development and scale up of fermentation processes from 500 mL to 30 L.

In our process development laboratory we have a 480sqft flexible hall, if you have a piece of equipment that needs the right infrastructure and dedicated space to make it work then our flexi hall could be the right place for it.

Our microbiology laboratory offers a range of equipment allowing users to safely handle, store and work with a variety of aerobic and anaerobic microbes at ACDP hazard category II level.

We have established a set of molecular analysis labs to enable a variety of genetic analysis applications to be carried out.

In order to get the most out of your biorenewable materials it is often necessary to prepare them for further use. This is especially the case with biomass (incl. waste), as these often have high water content and are bulky. So, we have a dedicated range of pre-processing equipment to be able to help from start to finish with your biomass – including drying, milling, pelletising and oil pressing.

The macerator is capable of reducing solids to small pieces; producing slurries and processing biomass materials with high water content.

Our microbiology laboratory offers a range of equipment allowing users to safely handle, store and work with a variety of aerobic and anaerobic microbes, at ACDP hazard category II level.

Pelletising is the process of compressing light material into the form of a pellet. This has many advantages, mainly by reducing dust in transport and increasing the density of the material being transported.

We have a range of pre-processing equipment to enable us to work with the interesting oils found in seed crops.

Size reduction equipment, such as a cutting mill, a hammer mill or a granulator, with capacities ranging from 4 kg/h to 100 kg/h.

Our processing equipment allows you to move from bench-top to pilot-scale testing, and has been selected to provide enough scale for you to make commercial decisions. Biorefining and chemical processing inevitably requires separations at some point in the process, and we have a variety of equipment to do this. In addition, we also have novel demonstration equipment, including spinning cone columns, supercritical CO2 and microwave heating technologies.

Our biogas facilities enable new/potential users of anaerobic digestion (AD) and biohydrogen to characterise their feedstock to establish its suitability for production of high gas yields.

Used for purification and separation of complex organic mixtures.

We have several bioreactor systems, which allow the development and scale up of fermentation processes from 500 mL to 30 L.

Our Guedu filter drier is used for separating solids and liquids from each other, before drying the products.

Gas chromatography (GC) is a flexible technique that allows separation and quantification of chemical substances found within a complex mixture.

The Buchi Kilo Suite (ATEX Rated 65 L vessel) pilot scale glass reactor suite has a 65 L capacity, capable of operating under various modes including reaction, distillation, crystallisation and extraction.

Our pyrolysis microwave allows heating up organic materials in the absence of oxygen (pyrolysis) for a wide range of industrial applications such as energy and chemicals production.

The RoboQbo 15-4 is a Universal Process Machine capable of processing high solid loading slurries upto 30% w/w (dependent on feedstock).

Our microbiology laboratory offers a range of equipment allowing users to safely handle, store and work with a variety of aerobic and anaerobic microbes, at ACDP hazard category II level.

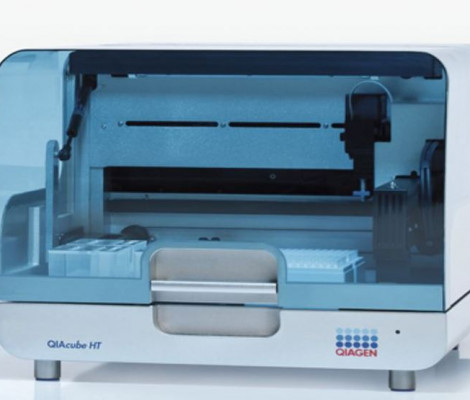

Qiagen QIAcube HT is an instrument for an automated mid- to high-throughput nucleic acid purification in 96-well format using silica membrane technology.

Our supercritical fluid extraction system at can extract chemical compounds from biomass materials.

The development of innovative bio-based products often requires a downstream processing stage, typically to separate out the chemical of interest. Following development at ‘bench-scale’ this often needs to be assessed at pilot scale – normally in the 1 – 100 litre or 1 – 100kg scale. We have a range of downstream processing technologies including various centrifuges, liquid-liquid separators, distillation instruments and filtration systems. Additional warehouse space can also be made available for larger tonne scale activities where business specific downstream processing capabilities can be set up and demonstrated as a route to investment into commercial scale plant.

We have a variety of analytical equipment available at the centre.

Our CINC counter current liquid-liquid separator allow liquid/liquid separation of two phases of differing density.

Used for purification and separation of complex organic mixtures.

Our Centritherm® (CT01-9RM) evaporator is one of our distillation units, which is particularly suitable for concentration of materials at relatively low temperatures.

We have a larger version of the Centritherm evaporator, the Flavourtech Spinning Cone, capable of handling up to 1 ton/h of material. The flavourtech spinning cone is a thin-film distillation column, consisting of 21 inverted cones.

Gas chromatography (GC) is a flexible technique that allows separation and quantification of chemical substances found within a complex mixture.

We have two pilot scale continuous centrifuges, capable of operating (depending on feedstock) at process feedstocks rates of up to 100 L/h.

We have several filtration units available at the BDC.

In the development of novel bio-based products, there is a requirement to evaluate performance of a range of physical, chemical and biological parameters to assess how the new product behaves in different environments. We have a range of capabilities to allow this evaluation to be performed including benchtop NMR to rapidly assess the properties of bio-based oils, chromatography to assess the chemical properties of products as well as Life Cycle Analysis, Techno-Economic Analysis and shelf life assessment protocols to look at product stability.

We have a variety of analytical equipment available at the centre.

The Benchtop NMR Analyser is based on Nuclear Magnetic Resonance (NMR) and allows for fast, accurate, reproducible and solvent-free measurement of oil, fat and moisture in oil seeds, seed cake and foodstuffs.

Gas chromatography (GC) is a flexible technique that allows separation and quantification of chemical substances found within a complex mixture.

Gas chromatography (GC) is a flexible technique that allows separation and quantification of chemical substances found within a complex mixture.

High Performance Liquid Chromatography (HPLC) is a flexible technique that allows separation and quantification of chemical substances found within a complex mixture.

Our microbiology laboratory offers a range of equipment allowing users to safely handle, store and work with a variety of aerobic and anaerobic microbes, at ACDP hazard category II level.

The Metrohm Rancimat helps us determine the oxidation stability of natural fats and oils. The instrument works on the principle of passing air through a test sample at an elevated temperature, causing accelerated aging of the sample.

We use plant growth trials to assess the performance of new products and processes, such as seed treatments and new bio-based fertilisers, or newly generated plant growth media incorporating bio-based materials or by-products.

As well as lab-based support, we also add value through market research activity and product or customer discovery research. Many businesses see us as an extension to their own team, where we provide an extra set of ideas to help solve a process challenge or accelerate a product or service improvement. All our facilities are open-access, if you know what you want to do but don’t have the equipment to do it, then we can also arrange for you to spend time in our labs working alongside our experienced team.

We work with bio-based businesses and projects to increase awareness of their products, processes or project.

If you are an entrepreneur or a start-up in the bioeconomy, we can help you develop and commercialise your product or process.

We have state-of-the-art research and development biorefinery, pilot scale laboratory facilities and flexible office space available for hire.

We add value through market research activity, new and existing product or customer discovery research.

We have been part of several international projects, our expertise range from project management, communication and dissemination support to accessing our research and development knowledge and equipment.

We have a vast amount of experience in managing national and international projects as well smaller one to one projects for our pre-funded support programmes aimed at regional SMEs.

As part of responsible research and innovation, we actively encourage our academic, industry partners and clients to examine the associated processes, including intellectual property as well as understanding the appropriate regulatory environment.

Bio-based materials including various types of waste, can be assessed to determine how they can be used to produce valuable products.