DyeRecycle: Scaling up circularity in textiles

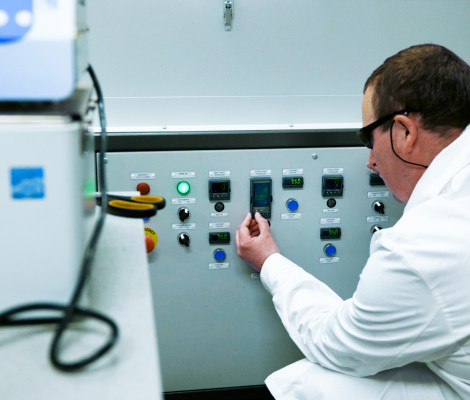

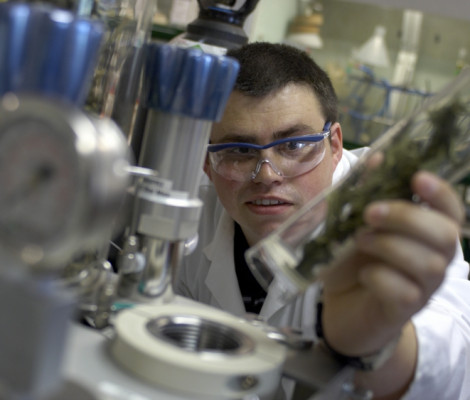

DyeRecycle represents a breakthrough in sustainable textile innovation, tackling one of the fashion industry's most pressing environmental challenges. As a pioneering pre-seed company, DyeRecycle has developed revolutionary chemical technology that transforms textile waste from an environmental burden into a valuable resource. Their approach enables the extraction and recycling of high-quality dyes from discarded textiles while simultaneously improving fibre recyclability, creating a truly circular system that addresses both waste reduction and resource recovery in the fashion industry.