Biogas facilities

Our biogas facilities enable new/potential users of anaerobic digestion (AD) and biohydrogen to characterise their feedstock to establish its suitability for production of high gas yields.

The pyrolysis microwave allows heating up organic materials in the absence of oxygen (pyrolysis) for a wide range of industrial applications such as energy and chemical production. This is in essence a domestic microwave’s big brother and allows us to heat up organic materials in the absence of oxygen (pyrolysis) for a wide range of industrial applications such as energy and chemical production.

Pyrolysis Microwave

This unit can pyrolyse a variety of biomass which can then be separated into bio-char and fractionated bio-oil using the integral product collection system. This microwave is capable of continuous flow up to 30 kg/hour at variable power (6 kW) and has been custom built by SAIREM for our facilities. This unit can pyrolyse a variety of biomass which can then be separated into bio-char and fractionated bio-oil using the integral product collection system.

In contrast to a domestic microwave, this machine is capable of continuous flow up to 30 kg/hour at variable power (6 kW) and has been custom built by SAIREM for the BDC. This unique patented technology was developed here at York and is particularly novel as it is a low temperature method (less than 200°C) and separates the bio-oil products into more useful groups. We have a long history of working with microwave technology for synthesis, extraction, hydrolysis and pyrolysis.

Our biogas facilities enable new/potential users of anaerobic digestion (AD) and biohydrogen to characterise their feedstock to establish its suitability for production of high gas yields.

Used for purification and separation of complex organic mixtures.

We have several bioreactor systems, which allow the development and scale up of fermentation processes from 500 mL to 30 L.

Our Guedu filter drier is used for separating solids and liquids from each other, before drying the products.

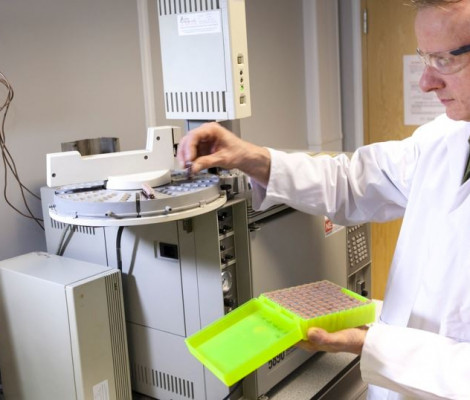

Gas chromatography (GC) is a flexible technique that allows separation and quantification of chemical substances found within a complex mixture.

The Buchi Kilo Suite (ATEX Rated 65 L vessel) pilot scale glass reactor suite has a 65 L capacity, capable of operating under various modes including reaction, distillation, crystallisation and extraction.

Our pyrolysis microwave allows heating up organic materials in the absence of oxygen (pyrolysis) for a wide range of industrial applications such as energy and chemicals production.

The RoboQbo 15-4 is a Universal Process Machine capable of processing high solid loading slurries upto 30% w/w (dependent on feedstock).

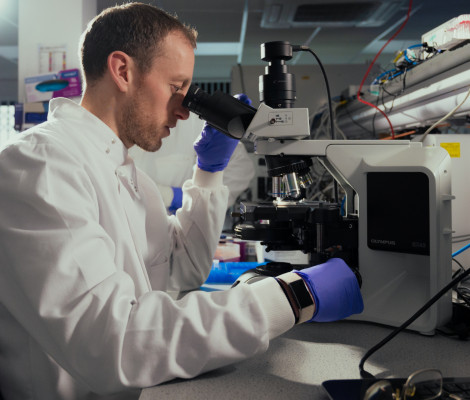

Our microbiology laboratory offers a range of equipment allowing users to safely handle, store and work with a variety of aerobic and anaerobic microbes, at ACDP hazard category II level.

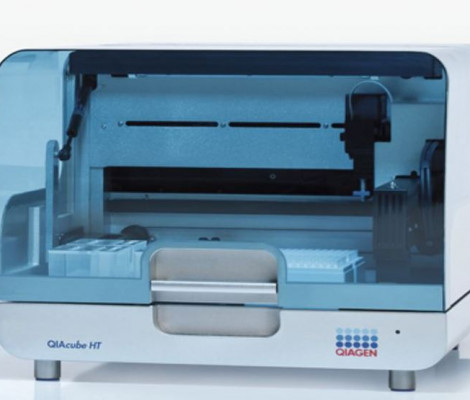

Qiagen QIAcube HT is an instrument for an automated mid- to high-throughput nucleic acid purification in 96-well format using silica membrane technology.

Our supercritical fluid extraction system at can extract chemical compounds from biomass materials.