Biogas facilities

Our biogas facilities enable new/potential users of anaerobic digestion (AD) and biohydrogen to characterise their feedstock to establish its suitability for production of high gas yields.

Our supercritical fluid extraction (SFE) system can extract chemical compounds from biomass materials.

This is an extraction and fractionation system which can be used for the separation of higher value materials from a range of dry solid materials. This method of extraction is commonly used for the removal of caffeine from tea and coffee.

Employment of carbon dioxide at sub- or supercritical conditions allows the extraction of materials such as waxes, lipids and secondary metabolites. In its supercritical state, carbon dioxide achieves high mass transfer rates, and consequently high extraction yields. Product recovery is simply achieved by release of pressure, without leaving solvent residues.

We have two 200 g/min liquid CO2 pumps arranged in parallel, and two 5 L pressure vessels rated to 650 bar, which can be heated to a maximum of 120 °C from two Julabo oil circulators. An automated back pressure regulator (ABPR) regulates the system’s pressure with the CO2 subsequently passing into three 1 L heated collectors with individual manual regulators for the fractionation of multiple components. The system can be operated under recirculation and non-recirculation modes.

This system comprises two extraction vessels with a combined working volume of 10 litres and it is capable of running at pressures up to 600 bar.

Our biogas facilities enable new/potential users of anaerobic digestion (AD) and biohydrogen to characterise their feedstock to establish its suitability for production of high gas yields.

Used for purification and separation of complex organic mixtures.

We have several bioreactor systems, which allow the development and scale up of fermentation processes from 500 mL to 30 L.

Our Guedu filter drier is used for separating solids and liquids from each other, before drying the products.

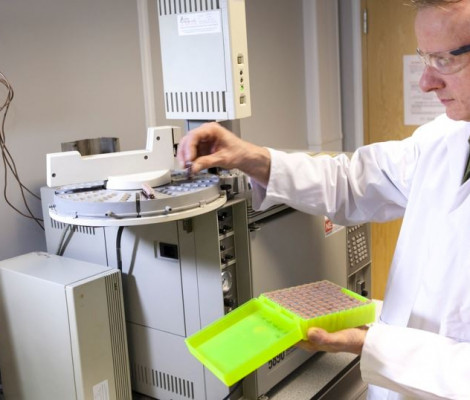

Gas chromatography (GC) is a flexible technique that allows separation and quantification of chemical substances found within a complex mixture.

The Buchi Kilo Suite (ATEX Rated 65 L vessel) pilot scale glass reactor suite has a 65 L capacity, capable of operating under various modes including reaction, distillation, crystallisation and extraction.

Our pyrolysis microwave allows heating up organic materials in the absence of oxygen (pyrolysis) for a wide range of industrial applications such as energy and chemicals production.

The RoboQbo 15-4 is a Universal Process Machine capable of processing high solid loading slurries upto 30% w/w (dependent on feedstock).

Our microbiology laboratory offers a range of equipment allowing users to safely handle, store and work with a variety of aerobic and anaerobic microbes, at ACDP hazard category II level.

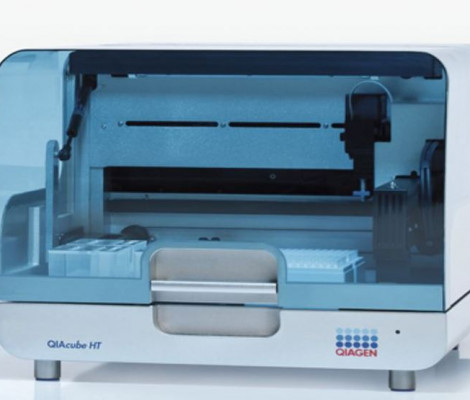

Qiagen QIAcube HT is an instrument for an automated mid- to high-throughput nucleic acid purification in 96-well format using silica membrane technology.

Our supercritical fluid extraction system at can extract chemical compounds from biomass materials.