Producing biohydrogen for the UK transport sector

Following on from the successful Hydrogen BECCS Innovation Programme Phase 1 funding for the H2Boost project, we and ten other partners have successfully been awarded £5 million for a phase 2 project. This is funded by the Net Zero Innovation Portfolio (NZIP) that has been awarded by the Department for Energy Security and Net Zero.

H2Boost will focus on demonstrating at scale a commercially viable and sustainable process for producing biohydrogen – a clean, gaseous biofuel created through microbial fermentation of organic waste.

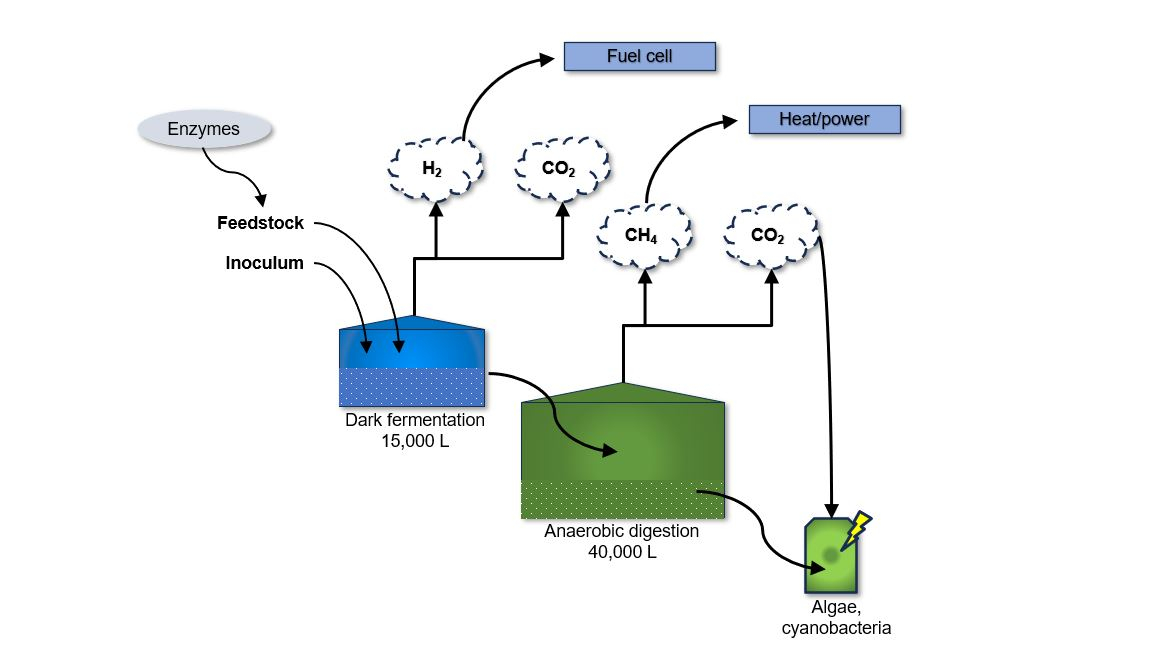

The project aims to produce biohydrogen for the UK transport sector by integrating an advanced oxidation and enzymatic pre-treatment technology of bio-based feedstocks, conversion to bio-hydrogen by dark fermentation (DF) and down-stream processing of by-products via anaerobic digestion, microbial CO2 capture and storage.

Phase 2 will look at under-utilised, low-value feedstocks that will be subjected to different pretreatment conditions to improve biohydrogen yields and reduce the residency time of nutrient-rich streams in DF. The fermentation by-products, namely anaerobic digestion digestate, will be used as substrates for algal propagation and anaerobic digestion to achieve a closed-loop system for enhanced biomethane yield and carbon capture and storage (CCS).

Building on the work of phase 1

This multi-step process aims to create a technology that is financially viable and environmentally sustainable. Input from the supply chain, market engagement, techno-economic and life cycle analysis will demonstrate process environmental and commercial sustainability.

Building a demonstration plant

At The Maltings (a food waste processing and recycling facility in South Milford, North Yorkshire) a demonstration biohydrogen production system will be built and organic waste will fuel the process. Product for the feedstocks at this scale will include green and food waste, as well as soiled card and paper. At lab scale a range of secondary feedstocks such as cosmetics waste and insect frass to assess their potential for future biohydrogen production.

A collaboration of academia and industry

To further develop this project, the consortium brings together academic research and industry. Project partners include; the University of Leeds, Qube Renewables, Aardvark EM, Cyanocapture Ltd, The Maltings Organic Treatment Ltd, AB Agri, NNFCC and CM90 Ltd.

Our role in the project

We have a broad and integrated role in the project. As well as leading on the management of the project, our scientists are working on the lab scale trials and the 10L continuous trials as well as the testing of alternative feedstocks and enzymes. Our innovation advisors are also involved in the policy and regulatory considerations and organising the industry facing workshops.

Aligning with the UK’s ambition of reaching net zero by 2050

The work undertaken by the consortium will contribute to the decarbonisation of the passenger and long-haulage transport sector which contributed to 16% of 2019 domestic GHG emissions. In addition, H2Boost objectives align with the UK ambition of reaching net-zero by 2050 with low carbon hydrogen-based technologies providing up to 35% of energy requirements. The growing demand for hydrogen to meet the UK net-zero ambitions will rely on processes such as those deployed by the H2Boost consortium.

The project combines expertise from academia and industry with support from a panel of external advisors on feedstock pre-treatment, fermentation, microbial analysis, and downstream processing. The integrated process developed by H2Boost partners will offer a novel reliable source of UK-produced low-carbon biohydrogen and high-value products with market applications such as biofertiliser and biofuels to help to address the use of high volume waste streams in generating biohydrogen.

The Hydrogen BECCS Innovation Programme supports technologies which can produce hydrogen from biogenic feedstocks and be combined with carbon capture. It forms part of the Department for Energy Security and Net Zero £1 billion Net Zero Innovation Portfolio, which aims to accelerate the commercialisation of innovative clean energy technologies and processes through the 2020s and 2030s. In total over £26 million of funding was awarded to enable 6 organisations, including 5 micro- and small- sized enterprises to deliver commercially viable hydrogen BECCS innovations.

Watch our webinars

Innovative processes and technologies for producing biohydrogen for the UK

During this webinar (which took place on 25th April 2024) our academic and industrial partners gave an overview of our ambitions and outputs to produce biohydrogen. These align with the UK's ambitious target of reaching net-zero by 2050, as low carbon hydrogen-based technologies provide up to 35% of energy requirements. The growing demand for hydrogen to meet the UK net-zero ambitions will rely on processes such as those deployed by H2Boost.

The slides from the webinar can be downloaded here.

Participate in H2Boost

H2Boost will run a number of events and industry-facing workshops to engage with our key stakeholders - further details to be announced shortly.

You can also keep up-to-date with the latest H2Boost project developments by following #H2Boost on X and LinkedIn.

Contact: penny.cunningham@york.ac.uk